Mail Us: [email protected]

Call For Us: +86 13826881930

Product Description:

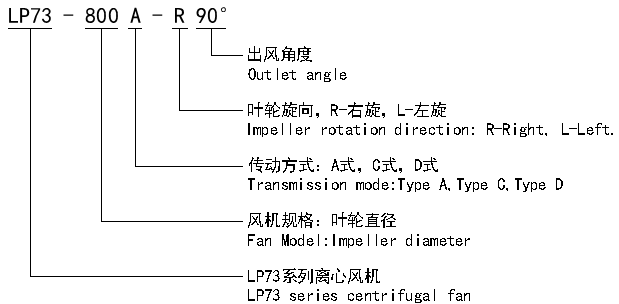

LP73 series centrifugal fan is a new series of high-efficiency series developed independently by our company for the use of industrial engineering and atmospheric control industry. It is characterized by high efficiency and low overall energy consumption of the equipment, and the energy efficiency index reaches the standard of Grade 1 energy efficiency

LP73 series fan is divided into A-type, C-type, and D-type transmissions. The fan mainly consists of components such as the casing, impeller, inlet, motor, and other accessories.

LP73 series fan is available in 9 specifications: 500, 560, 630, 710, 800, 900, 1000, 1120, and 1250.

Type-A transmission performance for LP73 series fan - Air volume: 3700-93000m³/h, Total pressure: 120-4200Pa.

Type-C transmission performance for LP73 series fan - Air volume: 4400-89000m³/h, Total pressure: 250-2600Pa.

Type-D transmission performance for LP73 series fan - Air volume: 3700-93000m³/h, Total pressure: 120-4200Pa.

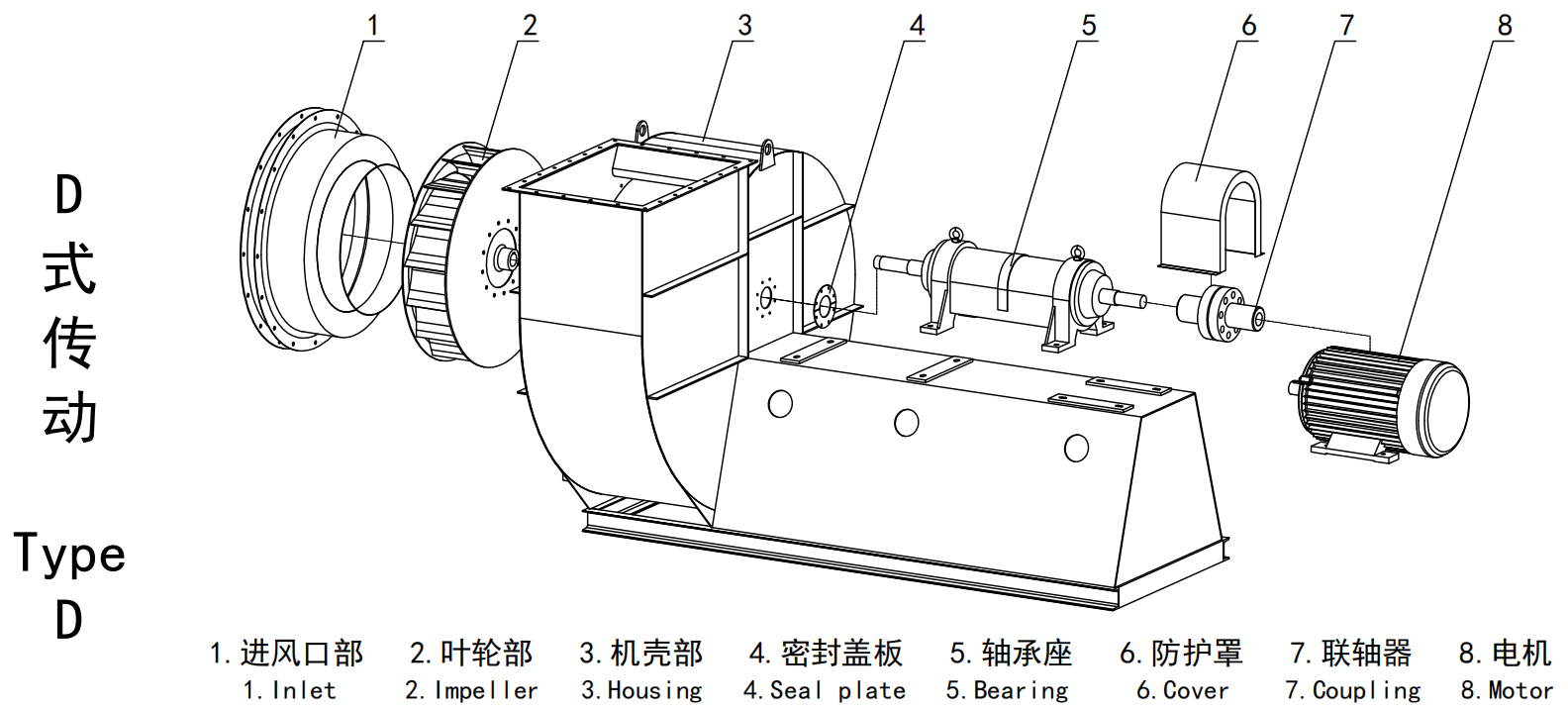

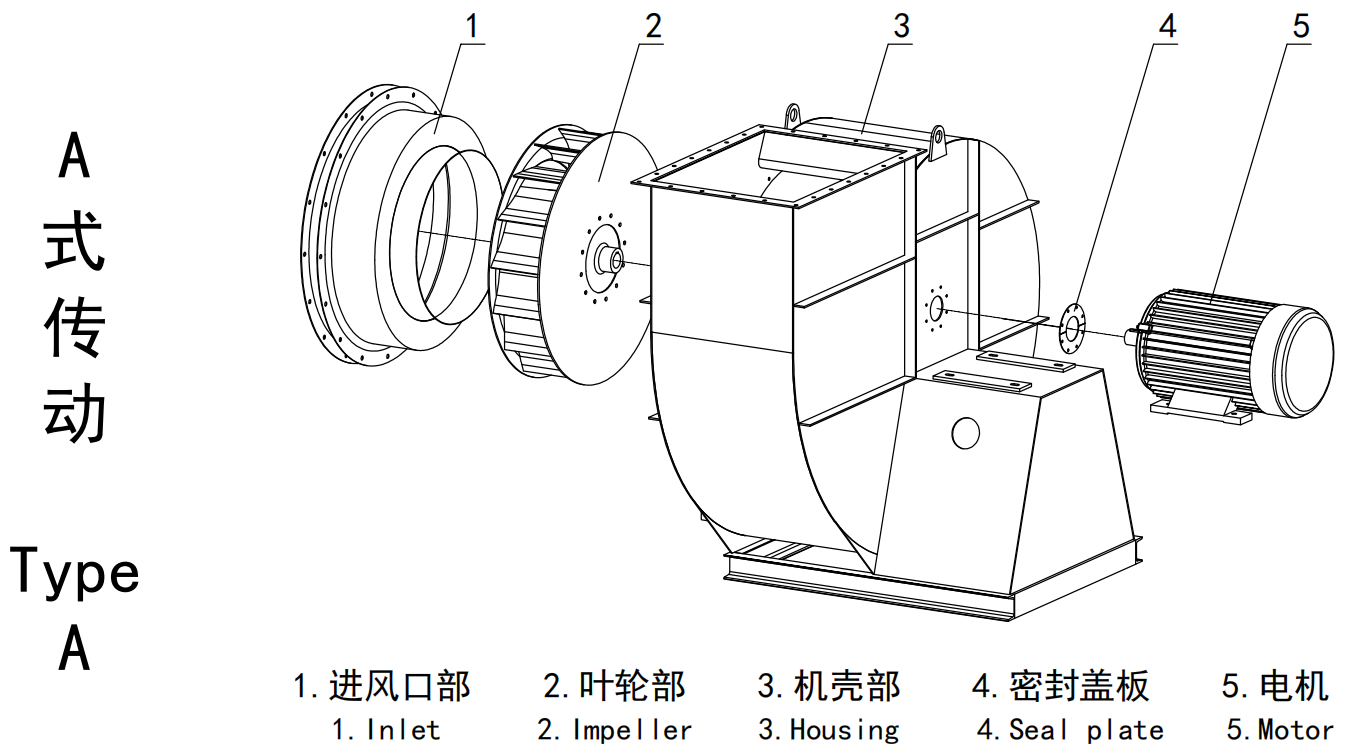

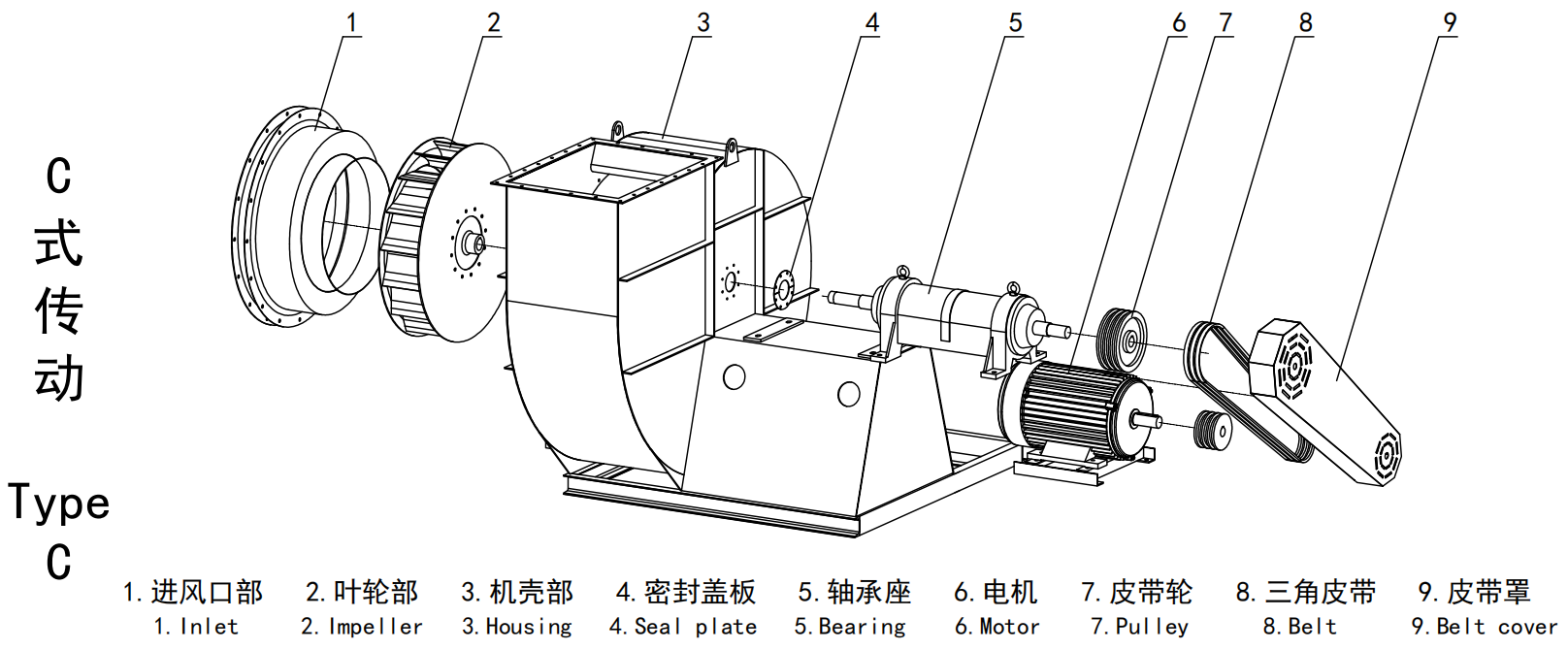

Driven Type & Structure:

LP73 series fan primarily adopts three transmission modes: A-type, C-type, and D-type. Additionally, fans with other transmission modes can be designed and produced according to customer requirements.

Type-A: Direct-coupling transmission with the motor. It features a compact structure and easy maintenance.

Type-C:Belt transmission. Its advantage lies in the ability to adjust the fan performance parameters by changing the speed, compensating for selection errors. However, belts are consumable components and require regular replacement.

Type-D:Coupling transmission. Compared to C-type, D-type has a more simplified and compact structure, reducing the size of the unit. However, it cannot change the fan speed.

Note: The fan components shown in the diagram may be subject to appropriate changes based on order requirements or specific usage scenarios. Actual items should be referred to for accuracy.

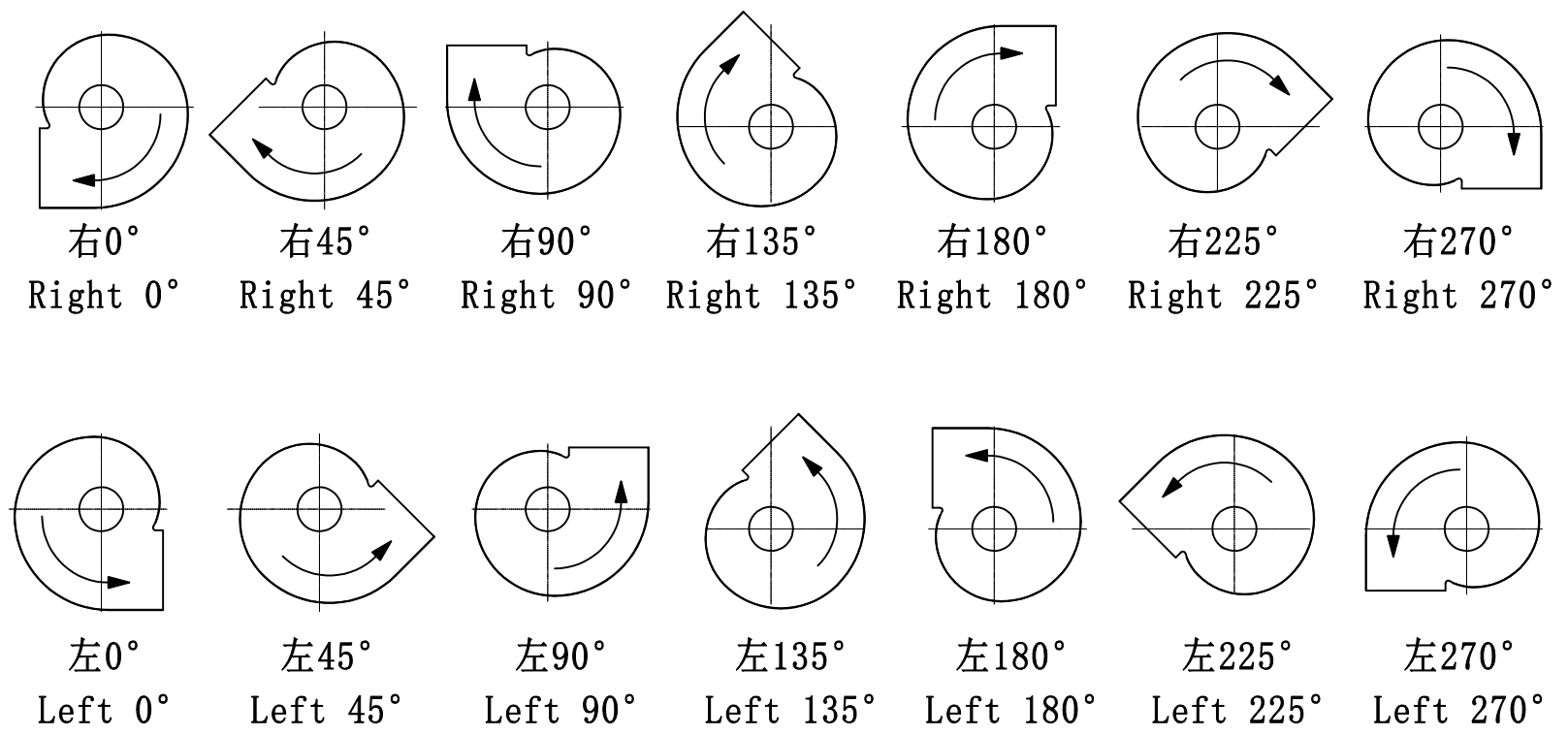

Direction Of Rotation & Outlet Angle:

1. According to the rotation direction of the impeller, the fan is divided into clockwise (right-hand) and counterclockwise (left-hand) rotation. When viewed from the drive end, if the impeller rotates clockwise, it is considered right-hand rotation, denoted as "Right"; if the impeller rotates counterclockwise, it is considered left-hand rotation, denoted as "Left".

2. According to the different positions of the outlet, the fan can be manufactured in 7 different angles (refer to the schematic diagram below). Our company's standard products include three angles: 0°, 90°, and 180°, and other angles can be customized based on customer requirements.

3. Note: The arrows in the diagram indicate the direction of the impeller's rotation.

Technical Note:

Q——流量 Air Volume(m³/h)

p——全压 Total pressure(Pa)

Nin——内功率 Shaft power(kW)

ηin——内效率 Internal efficiency

ρ——气体密度 Gas density(kg/m³)

(Note: The subscript with 0 is the standard state, and the subscript without 0 is the use state.)

•The fan performance parameters provided in this document are based on standard conditions: clean air at standard atmospheric pressure, a temperature of 20°C, and air density of 1.2 kg/m³. If the fan is used under non-standard conditions, the parameters should be converted to standard conditions for proper selection.

•When the operating conditions are non-standard or the fan speed varies, it is necessary to convert the performance from non-standard to standard conditions and then select the fan based on the converted performance. The conversion formula is as follows:

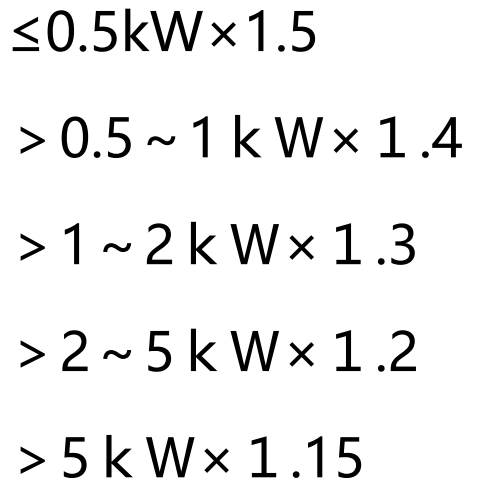

•The power curve in the performance curve chart refers to the shaft power of the fan. When selecting the motor power, it is necessary to consider the following safety factors:

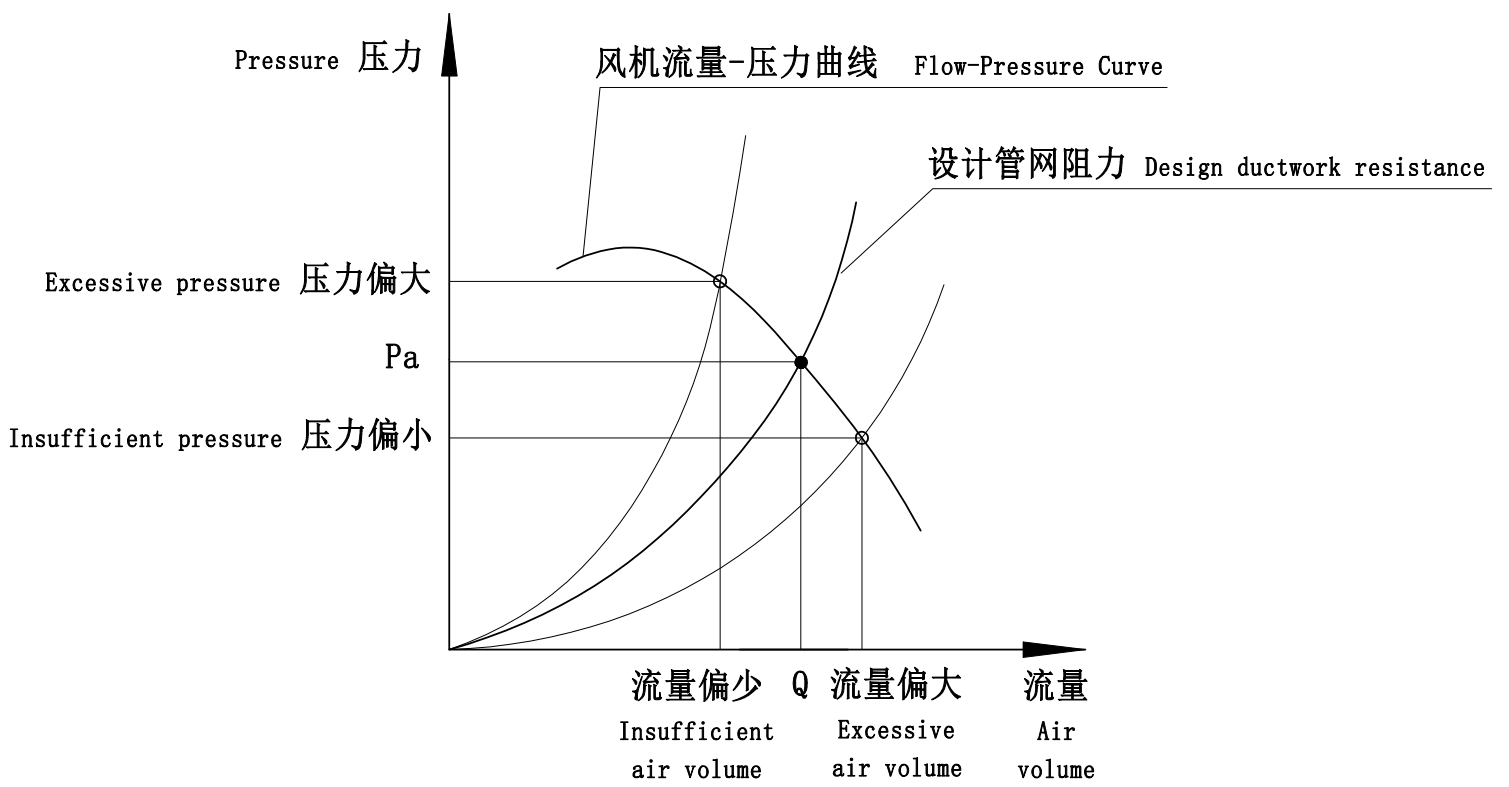

•During the use of the ventilation fan, it is common to encounter situations where the airflow is either too high or too low. This is mainly due to inaccurate resistance design of the duct system or changes in duct resistance. If, during usage, the airflow gradually decreases over a longer period or suddenly decreases in a short time, it is mainly due to duct blockage.

Usage & Service Condition:

1. Usage scenarios: It can serve as supporting equipment for environmental purification facilities and air treatment facilities; it is also widely applicable in large and medium-sized factories, civil buildings, large squares, power plants, and other places.

2. Medium Requirements: The conveyed medium should be air or other non-corrosive, non-flammable, non-explosive gases, and the gas should not contain sticky substances. The dust and solid particle content in the gas should not exceed 150mg/m³. If used for conveying small particle materials, the service life of the fan impeller will be shortened.

3. Conveyed Medium Temperature: The standard fan is designed to convey medium with a temperature not exceeding 80°C.

Attention:

·When the environment demands higher vibration standards for the fan, such as when the fan is installed on a floor, vibration dampers can be used as auxiliary equipment. When selecting, it should be noted that standard fan configurations do not include vibration dampers. Users can purchase dampers separately or specify the inclusion of dampers when ordering the fan.

·Fan accessories can be configured according to user requirements, such as regulating mechanisms (adjustment dampers and control linkages), control systems (control cabinets, starting cabinets, and operation boxes), protective mechanisms (various temperature and vibration measuring instruments, soft connections, and expansion joints for pipeline systems), and other items like silencers, electric actuators, and fluid couplings. It is essential to specify these requirements when placing an order.

·When the fan is intended for conveying high-temperature medium (medium temperature exceeding 80°C), it is important to specify this requirement when placing the order.

Attention Of Ordering:

After selecting the desired fan, please proceed with the order according to the following points:

·Fan Model: This includes the machine number, rotation direction, outlet angle, and transmission mode, among other specifications.

·Operating point performance parameters under standard conditions, including the fan's airflow, total pressure (static pressure), and speed.

·The motor's brand, frequency, voltage, insulation class, and protection level.

·The quantity for procurement.

·Any other special requirements, such as adding vibration dampers or fan accessories, etc.

Model description:

Copyright © © Copyright 2024 Guangdong Leapin Environmental Technology Company,Ltd All rights reservedPrivacy Policy