Cabinet fans: a versatile ventilation solution

Why Cabinet Fans Are Essential for Versatile Ventilation Solutions

Cabinet fans play a crucial role in industrial and commercial environments by facilitating effective airflow and temperature management. These fans are expertly designed to exhaust unwanted air from enclosures or spaces, ensuring that equipment functions within safe temperature ranges. This not only reduces the risk of overheating but also extends the longevity of machinery—a fact substantiated by various studies on equipment durability. With their ability to manage high-temperature environments, cabinet fans become indispensable in settings where maintaining an optimal climate is vital for productivity and equipment safety.

The primary benefits of using cabinet fans include enhanced airflow management, energy efficiency, and improved indoor air quality. By maintaining a consistent air circulation, they help in reducing humidity levels, controlling odors, and creating a more comfortable atmosphere for employees and equipment alike. Additionally, cabinet fans can lead to significant energy savings by lowering reliance on more extensive and expensive cooling systems. Various energy savings reports suggest that incorporating these fans can reduce cooling costs, making them a cost-effective solution in the long term. Their utility in diverse applications solidifies their importance in offering versatile ventilation solutions.

These advantages make cabinet fans a wise choice for facilities looking to enhance their ventilation capabilities while simultaneously managing energy consumption and equipment health.

Exploring the LT-FC Series Cabinet Fan

Key Features of the LT-FC Series

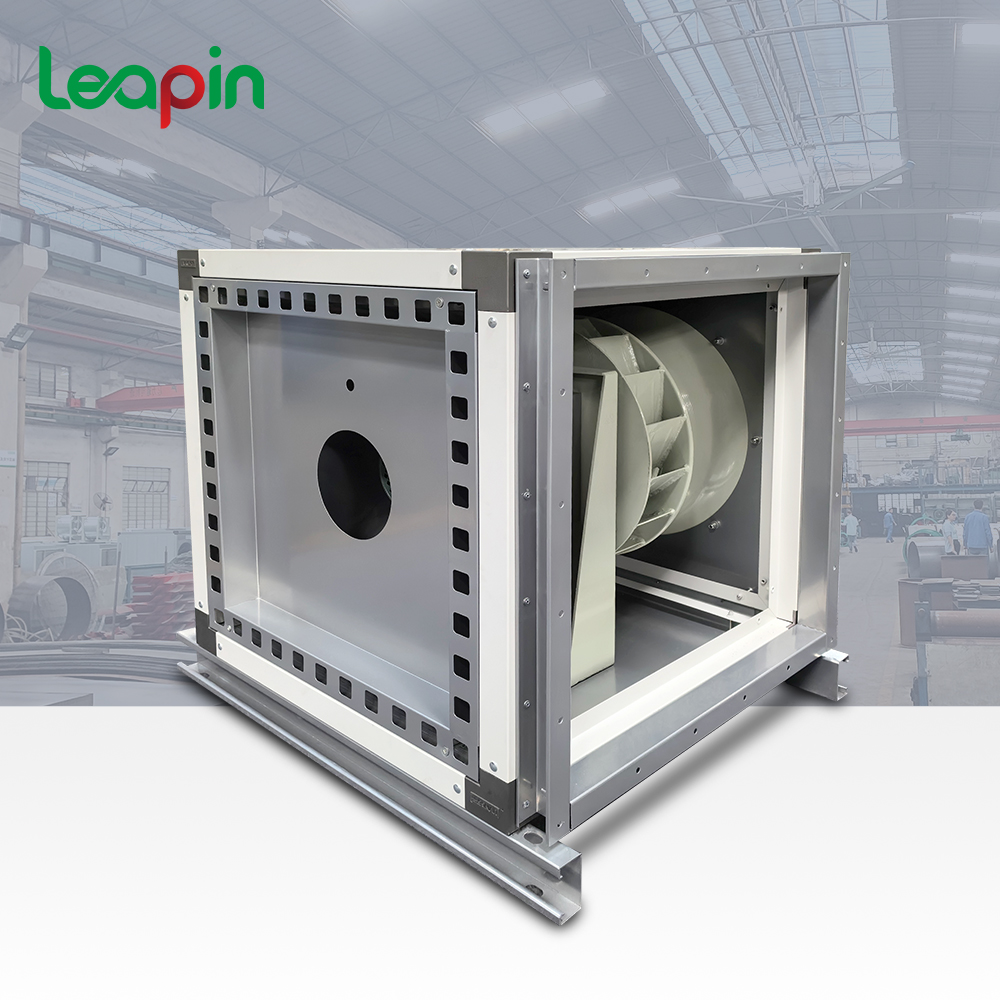

The LT-FC Series cabinet fan exemplifies a compact design that prioritizes energy efficiency without compromising on performance. Key features include thermal overload protection and adjustable speed controls, allowing airflow optimization based on specific needs. This series employs advanced centrifugal fan technology, ensuring robust airflow while maintaining a quiet operation—a significant advantage in environments where noise levels are a concern. Sound level testing verifies its suitability for noise-sensitive applications, showcasing the LT-FC Series' efficiency in delivering powerful yet quiet ventilation solutions.

Applications of the LT-FC Series in Various Environments

LT-FC Series cabinet fans are integral to maintaining efficient air movement in a variety of environments. They cater to industrial applications such as server rooms, manufacturing facilities, and warehouses, where optimal air circulation is crucial for equipment longevity and performance. In commercial settings, including retail stores and wineries, these fans manage consistent temperature and humidity levels to enhance both product quality and customer experience. Case studies have demonstrated the LT-FC Series' effectiveness across these diverse environments, affirming its role in comprehensive ventilation strategies for both industrial and commercial sectors.

The LT-BC Series Cabinet Fan: A High-Performance Option

Advantages of the LT-BC Series

The LT-BC Series cabinet fan is crafted for applications requiring high airflow and pressure, making it ideal for robust ventilation solutions. Its design emphasizes durability, allowing it to perform efficiently in harsh environments and withstand prolonged use. The fan utilizes a backward-inclined centrifugal impeller to ensure high performance even under demanding conditions. Moreover, its versatility in mounting options—either inline or cabinet—enables it to suit various space and airflow needs effectively. Studies on installation practices highlight how this flexibility allows for custom configurations, optimizing ventilation performance based on specific environmental requirements.

Where to Use the LT-BC Series for Optimal Results

Optimal implementation of the LT-BC Series cabinet fan is found in environments demanding high-performance ventilation—particularly in high-heat industrial processes and large machinery enclosures. These settings benefit most from the LT-BC's efficient air movement capabilities. Furthermore, clean rooms or laboratories, where stringent air filtration is crucial, gain from its robust design. Comprehensive evaluations by experts suggest this fan's ability to enhance airflow, ensuring contaminants are efficiently managed, aligning with the needs of such controlled environments. The fan’s capability to maintain air quality in these areas underscores its reliability and effectiveness in maintaining operational excellence.

PFHP Cabinet Fan Series: A Durable and Efficient Choice

Specifications and Features of the PFHP Series

The PFHP Series cabinet fan is renowned for its high efficiency and robust construction, making it ideal for continuous operation in demanding environments. Key specifications include energy-efficient motor designs and customizable airflow settings that adapt to varied industrial needs. This series is engineered with longevity in mind and features corrosion-resistant materials, making it suitable for industries with harsh operating conditions. This adaptability and durability are substantiated by the manufacturer's specifications, ensuring that the PFHP Series is a reliable choice for businesses seeking stable and long-term ventilation solutions.

Ideal Use Cases for the PFHP Series

The PFHP Series is specifically designed to excel in environments like heavy manufacturing and automotive applications, ensuring efficient process ventilation in compliance with industry safety standards. It also performs effectively in areas requiring ventilation for chemical processes. Moreover, the PFHP Series is ideal for agricultural applications, where it can ventilate livestock areas to maintain a healthier atmosphere, contributing to improved well-being and productivity. These applications are backed by industry reports detailing how environment optimization with reliable ventilation solutions can enhance operational efficiency and safety.

How to Choose the Right Cabinet Fan for Your Needs

Selecting the right cabinet fan for your needs requires careful consideration of several key factors. Firstly, it is vital to evaluate the required airflow rates to ensure the fan can handle the volume of air needed for your specific application. Noise regulations should also be considered, especially in environments where sound minimization is crucial. Furthermore, consider the environmental conditions where the fan will be installed, ensuring that the chosen model can withstand these specifics.

Additionally, comparing different fan models based on performance ratings, energy efficiency, and maintenance requirements will facilitate a well-informed choice. Reviewing these aspects can help identify models that promise cost savings and reduced environmental impact in the long run. Consulting with HVAC experts can provide valuable insights into the best options available, as these professionals are well-versed with industry guidelines and advancements in fan technology. According to HVAC industry guidelines, expert advice can be instrumental in navigating complex choices and finding a suitable cabinet fan that meets your operational requirements.

Installation and Maintenance Tips for Cabinet Fans

Proper installation and maintenance of cabinet fans ensure longevity and performance. When installing a cabinet fan, it is crucial to allow sufficient space for airflow and adhere meticulously to the manufacturer's guidelines for mounting and electrical connections. This guarantees optimal operation and safety. Additionally, fan speeds should be adjusted according to the specific requirements of the environment to ensure efficient performance.

Regular maintenance is key to extending the lifespan of cabinet fans. Essential practices include cleaning the fan blades to prevent dust accumulation, checking for obstructions in the ventilation paths, and performing habitual electrical checks to avoid potential malfunctions. Following maintenance checklists can help identify issues before they become significant problems, thereby ensuring the fans remain effective. Engaging in these routine checks not only protects the equipment but also contributes to maintaining an ideal flow and pressure, which are vital for "industrial fans" and other fans in rigorous environments like workshops and factories.

EN

EN

AR

AR

FR

FR

RU

RU

ES

ES

TL

TL

ID

ID

VI

VI

TH

TH

MS

MS

BN

BN